What does it mean to have a Patent Pending, and what are the benefits of being Patent Pending?

Patent Attorney, Toni Tease and Product Designer, David Yakos explore the perks of having a patent pending, and how it can impact the future of your invention.

Click the video below to listen in on their conversation, and check out other Patent Law Q&A videos on the Salient Technologies YouTube Channel

Find more info on Ms. Tease at her website teaselaw.com, and check out her blog Intellections®

David Yakos is Co-Owner and Director of Creativity at Salient Technologies, Inc.

Kickstarter Success, New Employees & Patent Law

Client News: PowerPod Kickstarter campaign successfully funded!

Salient client, Velocomp successfully funded their Kickstarter campaign for the PowerPod cycling meter this past September, raising over $128K of their $50K goal in just 30 days!

Salient client, Velocomp successfully funded their Kickstarter campaign for the PowerPod cycling meter this past September, raising over $128K of their $50K goal in just 30 days!

PowerPod is a bicycle power meter that uses Velocomp’s patented power measurement technology. When c

ycling, more power means faster speeds and longer distances; better physical fitness and calorie burning.

Salient continues to support John Hamann and the Velocomp team as pre-production and tooling begin this November and production begins in the next week. If all goes according to plan, Velocomp will begin shipping fulfillment orders from their headquarters in Jupiter, FL by the end of the month. Check out the PowerPod Kickstarter campaign and post-campaign

updates here. Great work, guys!

Salient News: New Employee, Kirk Turner

The Salient team grew this June with the addition of Kirk Turner.

Originally from Maine, Kirk migrated west to the University of Utah before attending Western Washington University, where he graduated with a BS in Industrial Design and a minor in Sustainable Design in 2014. Happy to relocate to Bozeman and all the outdoor activities it has to offer, Kirk is an avid fisherman, skier, climber, cyclist and adventurer.

Kirk brings creative, precision artistry to Salient, and has expanded our in-house capabilities with his excellent Industrial Design chops.We’re excited to have Kirk on board, and all the skills he brings to the table!

Product Design Tools: Patent Law Q&A Series with Toni Tease & David Yakos

Filing for a patent, and the entire patent process can be intimidating and confusing. This spring, Salient’s David Yakos sat down with patent attorney Toni Tease of Intellectual Property and Technology Law to break down the patent process into bite size pieces. You can view the Q&A series on the Salient YouTube channel. We’re still adding episodes, so check back for new videos!

Salient 2015 Highlights

Another year has gone by, and here at Salient, we have a lot of things to be excited about! Here are just a few (in no particular order):

- The “inherently leak free” valves developed by Salient for Big Horn Valve passed

two of the most stringent tests for oil and gas

valves validating the technology as “emission-free” and the “Best Available Valve Technology to keep our environment green and clean”. - Salient President and Co-owner, Steve Sanford was recognized in the Southwest Montana 20 Under 40; people, entrepreneurs and employees in southwest Montana who have achieved success and improved the quality of life for others in their communities.

- Salient’s David Yakos and maker, Parker Thomas, co-presented “The Mindset of a Maker” at PlayCon 2015

- Salient leadership team experienced HATCH2015, a summit of 100 thought leaders from around the world to HATCH a better world.

- iBike Powerpod Kickstarter Success reaching 150% of their goal, and already fulfilling orders.

- The Salient team had 4 amazing college students shadow them on real life projects as part of Salient’s mentorship program

- Launch of the award-winning Maker Studio Construction Sets to inspire youth in engineering

and creativity, co-invented by David Yakos - Kickstarter success for Hydaway collapsible water bottle – backed by over 5,700 supporters, and raising over $260,000, 13x their goal!

- The Salient team is growing with with the addition of master Industrial Designer, Kirk Turner

- Team Salient helped facilitate HATCHedu to Design the School of the Future at DSEL Labs, Montana State University.

- Salient Co-owner, David Yakos was recognized in Origin magazine’s 45 Top Creatives

- In 2015, Salient provided Industrial Design, Prototype Development and Manufacturing Drawings for over 100 client products.

Five Reasons Markers are Not Dead

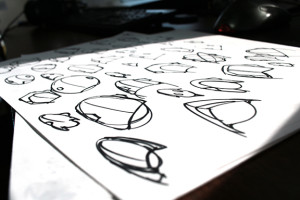

“Rumors of my demise are greatly over exaggerated” is not only a famous quote (Mark Twain) and song lyric (Rise Against the Machine), it also accurately describes the state of markers as a tool in the product development and design industry. Long gone are the days when painstaking hours were spent on full color, hand-drawn marker renderings (thank goodness!). However, I propose marker usefulness on a daily basis has not diminished. Here are just five reasons to not write off this somewhat archaic technology:

- Intentionally Imprecise: A chisel or wide

tipped sharpie is a great tool for quickly exploring a basic overall shape without getting caught up in details that aren’t yet pertinent. Our industry is detail oriented, and yet large markers can force you to be intentionally vague, work quickly, redirect focus to the 10,000 ft. view, cover ground and experiment with very few consequences. Fail quick, fail often and move forward more informed.

tipped sharpie is a great tool for quickly exploring a basic overall shape without getting caught up in details that aren’t yet pertinent. Our industry is detail oriented, and yet large markers can force you to be intentionally vague, work quickly, redirect focus to the 10,000 ft. view, cover ground and experiment with very few consequences. Fail quick, fail often and move forward more informed.

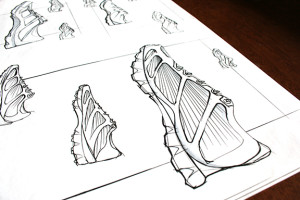

- Line Weight: This single attribute is often

what separates a great looking sketch from a less successful version. Thickness of lines is one of the quickest methods to show depth: is the line the closest one to the ground? Thick. Is the line a significant edge not attached to the bottom? Medium. Is the line an interior or contour line? Thin. Yeah, there are nuances to these rules, but if you’re not already using them, these simple guidelines will take your sketches to a whole new level. One thin pen, one medium, and one thick marker and you are in business.

what separates a great looking sketch from a less successful version. Thickness of lines is one of the quickest methods to show depth: is the line the closest one to the ground? Thick. Is the line a significant edge not attached to the bottom? Medium. Is the line an interior or contour line? Thin. Yeah, there are nuances to these rules, but if you’re not already using them, these simple guidelines will take your sketches to a whole new level. One thin pen, one medium, and one thick marker and you are in business.

- Depth: Low fidelity sketches are generally the next step after loose thumbnails. Photoshop brushes and masking can absolutely get the job done well, but they also require scanning your linework, color balancing etc. If getting the basic surfacing ideas across quickly is the most important goal, then contour lines are useful, but can quickly become distracting. By contrast, two gray scale markers in different values (20% and 50%, or 30% and 60%) can quickly add significant depth to any linework in less time than it would take to even prepare a file for digital shading.

- Color Exploration: There’s no need to own

a 72 pack with 7 shades of orange, but a basic 12 color set can be very handy to have on your desk. Say you’re are working on a water bottle and already have the general shape worked out in analog or digital formats… Scan the original sketch, duplicate, arrange in neat organized rows, and print it out. What does it look like in blue? How does a green grip affect the overall value or impact? You are only seconds away from finding out! This process is a great tool for building consensus at a design review, as everyone can quickly have a say, and there’s less “what if” conjecturing.

a 72 pack with 7 shades of orange, but a basic 12 color set can be very handy to have on your desk. Say you’re are working on a water bottle and already have the general shape worked out in analog or digital formats… Scan the original sketch, duplicate, arrange in neat organized rows, and print it out. What does it look like in blue? How does a green grip affect the overall value or impact? You are only seconds away from finding out! This process is a great tool for building consensus at a design review, as everyone can quickly have a say, and there’s less “what if” conjecturing.

- Simplicity: Have you ever tried to drag

a giant drawing tablet or computer to the airport, on a bus, or even home from work in the evening? While being amazing tools, portability is a distinct drawback. Digital sketching and rendering absolutely have their advantages, but when I can grab some pens, markers and paper, sit down on a flat surface – anywhere in the world – and problem solve a design that others can visually understand in minutes, that’s a distinct advantage, and a force to be reckoned with.

a giant drawing tablet or computer to the airport, on a bus, or even home from work in the evening? While being amazing tools, portability is a distinct drawback. Digital sketching and rendering absolutely have their advantages, but when I can grab some pens, markers and paper, sit down on a flat surface – anywhere in the world – and problem solve a design that others can visually understand in minutes, that’s a distinct advantage, and a force to be reckoned with.

Although the tools of product design continue to evolve in this increasingly digital world, don’t shelve those Prismacolor or Copic markers just yet. You may never do a 6 hour rendering by hand again in your life, but don’t dismiss an incredibly useful tool entirely just because it’s a little antiquated. If nothing else, at the end of the day, analog tools will never run out of battery power…. which is more than we can say about too many products in our daily lives.

Kirk Turner is an Industrial Designer, and has been bringing his brand of expertise to the Salient Team since 2015.

Salient-Helio Collaboration: 3D Printed Titles

Earlier this spring, Zach Johaneson of Helio Collective approached Salient about creating physical movie titles for use in-camera (instead of the typical computer-generated graphics we’re all used to seeing) for the opening credits of Red Bull’s recently-released Travis Rice snowboarding film, The Fourth Phase.

From Zach:

“For intro title sequences in films, you always start by identifying how the sequence should contribute to the film at large. For The Fourth Phase, Director Jon “JK” Klaczkiewicz had a vision of starting the film off with an elemental look at the hydrocycle. Helio & Co. has been in the graphics business for about ten years now, but with this project we really wanted to push ourselves into trying something different that would also contribute to the films overarching story. This is where the idea to shoot all of the titles in camera was born, but the execution was a total mystery. After a bit of experimentation, we reached out to Salient Technologies and they helped us realize we could actually 3D print very small titles that we could then place in these different states of water. For one instance, Salient 3D printed an incredibly small and detailed title and a jig so we could freeze it into a solid block of ice and then film it. Their ability to understand our end goal and then engineer solutions to achieve those goals was absolutely critical to our success.”

Salient and Helio explored many methods for fabricating the titles, including SLA (Stereolithography) and SLS (Selective Laser Sintering) 3D printing, laser cutting, decal cutting, and waterjet cutting.

In the end, due to size and quality constraints, we settled on SLS and SLA printing for the titles. For some of the close-up macro shots, the letters were minute – as tiny as 2mm tall. Since they were to to be shot at 6K resolution, the prints had to be very detailed and high-quality. Take a peek at the end result here:

The Fourth Phase: Opening Title Sequence from Helio + Company on Vimeo.

If you were especially perceptive, you may have noticed that “Principal” was misspelled (or misused) in a couple of the images, then corrected in the intro sequence with several more names added. A consequence of actually printing out titles and creating complex setups for filming in-camera effects (as opposed to using computer-generated graphics) is that when there are changes, they take considerably more time to fabricate. Re-printing, finish, setting up the shot, re-shooting, and re-editing is far more time-consuming than editing the spelling or content in a video program digitally, and then re-rendering. To our knowledge, this is the first use of 3D printed titles in a feature film, which is pretty exciting. Being pioneers, and making “firsts” takes sacrifice!

[rev_slider alias=”Helio Photos”][/rev_slider]

All images in slideshow were provided and used with the permission of Helio + Company. Helio staff featured in photos include Alex Gappa, Zach, Johaneson and Jim Menkol.

To see other work from Helio & Co, go to www.wearehelio.com

Fourth Phase 4K Trailer https://www.youtube.com/watch?v=2JHE2zkRfW4

Extra-Special Overalls

Fly fishing is popular here in Bozeman, MT… Children named Madison sit in most elementary classrooms. Summer sees the university students (some called Madison) from Montana State (aka Trout U) disembark for their break as anglers far-and-wide school to the trout-rich waters of the Missouri watershed. Toyota pickups haul drift-boats and dressed-down business magnates on guided pilgrimages to the Madison, Missouri, and Yellowstone…. while scruffy locals haul their Toyota pickups to favorite streams. The “intellectual capital” of a good piece of water– those glorious little capillaries where God Himself surely smiles on the solidarity and good bite that greets the invested angler– is worth as much to the visitors as the gold that brought Western man to Southwest Montana 150 years ago; and even more to the people that live here year-round.

I fish. I like it.

For years, I wet-waded from March through October. At 6’7″ and 180 lbs, manufactured fishing waders have never been an option. I have a 37″ inseam and 33″ waist, and the price to slide into a pair of those extra-special overalls seemED (emphasis on past tense) a little too “extra-“ for me.

It’s an entirely different blog post for another time, but modern garment grading (the process that creates the various sizes of a garment; usually S, M, L, XL in sportswear) fails to fit a conspicuous portion of the market: tall/slim builds; long arms; small waist/large thighs; petite women; large busts. It’s not anyone’s fault, that’s the status quo— a necessary evil to enjoy the quality and level of detail in a state-of-the-art piece of clothing—or is it?… But again, it’s a different bite of the elephant than we’ll take today.

So what to do? Like any reasonable person, I decided to make a pair.

I’ll admit, I am critical of the state of design for fishing waders. The level of detail shown – especially in construction – in some of the alpinism kits hasn’t transferred to the fishing market. The clean aesthetic that bonding technology can provide are not only hyper-modern, but more efficient for applications requiring waterproofness, avoiding material stack-up, registration, and if you pick your battles, labor. I aimed to make a rendition of wader design that centered around being “sleek”—low fuss, elegant, non-decorative. Truth be told, my everyday dress is quite “square”—I like traditional cuts and traditional aesthetics, but I wanted to make something unlike what anyone has seen…. Spoiler: it 80% worked.

Keep in mind: the full design and fabrication of these waders were on my own time after-hours over the winter season, and had only a single iteration in full-on waterproof breathable fabric, that is: the final iteration.

You can see from the process photographs that the first patterns were mocked up out of my favorite WPB substitute: painter’s plastic—wonderfully stable, with a hand similar to most 3-layer WPB, and CHEAP. It took nine iterations of pattern prototypes to block and then cut a final pattern that I was comfortable moving into the final fabric/construction with. As it came together, it fit as I expected. I chose to go stockingfoot on this pair—what I hadn’t foreseen, nor could try in the plastic prototypes, was how installing the neoprene booties would change the fit; constraining the lower leg. For all my “clever” patterning—the darts, billows, ease, and gussets—and prototyping, there were still factors I did not imagine that manifested themselves in the designed material.

Quick plug: this is where Salient design process thrives—material testing and R&D to work out process, material, and technical construction issues: chemical compatibility, patterning, material choice, cost reduction. We complete our work on-site, and in good time, getting answers from our studio/lab/shop to our clients faster and more clearly than a factory may.

I used the waders all year long with no failures: high, cold water in the springtime Missouri, low small-stream fishing, floating on the bitterly cold Big Hole, and finger-freezing brown trout runs. I see their value, and I know the amount of work that goes into them… fishing waders are a lovely piece of kit, and I am happy to have them now.

That lower leg, though… I might have to make a revised pair….

Seth Carlstrom is the head of the Soft Goods department at Salient. He has a degree in Mechanical Engineering from “Trout U”, textile certification from NC State, and was producing performance garments and gear to fit his lanky frame long before being introduced to industry.

Process Practice Makes It Perfect

If you want to be good at basketball, it’s likely you’d spend hours dribbling, working on your layups, and shooting three pointers. Chances are, you wouldn’t go out to play only on Game Day when it’s all on the line, and hope for the best. Personally I’m not much of a ball-sports guy, but the analogy works.

Here at the Salient Soft Goods Department, we stay pretty busy with client projects on a daily basis, but unfortunately, much of that work cannot be shared with the public. Many of the staff members, including myself, still try to make time to keep our skills sharp through continued practice in personal projects. My most recent project is a classic soft goods item: the backpack. Here are some of the individual steps – lets walk through them together.

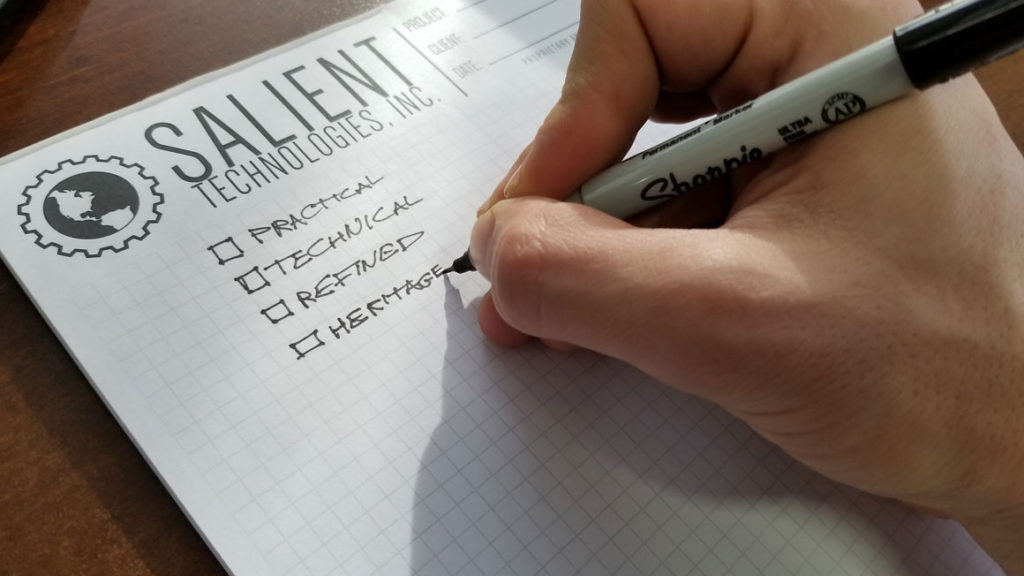

1.  Defining a set of goals, styles, influences and attributes is a great place to start. These items can really help inform the projects direction, feel, and vision; and they can be used as a benchmark for individual questions and construction details later on.

Defining a set of goals, styles, influences and attributes is a great place to start. These items can really help inform the projects direction, feel, and vision; and they can be used as a benchmark for individual questions and construction details later on.

2. A mood board or inspiration sheet allows you to examine different industries, specific materials, and any other items you might feel compelled to draw creativity from.

3. Sketch, sketch, sketch! I chose to focus on angular planes and shapes with rounded aspects dispersed throughout.

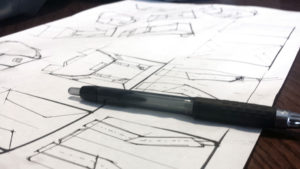

4. Define the basic dimensions. This can be done with paper/cardboard or computer programs – if you have access and knowledge.

5. Illustrate, define panels and construction details, pattern, and prepare to start fabrication. Alignment notches are your friends – use them! Patterning is an art in and of itself.

6. Gather materials and hardware. Local sources will have some items and can be a good start point, however, unless you have access to a specialty retailer, the internet might be the easiest place to purchase more technically oriented materials.

7. Cut and prepare materials. Laser cutters are amazingly accurate and fast tools, but good ol’ scissors have served well for many years prior to fancy, modern equipment.

8. Work backwards. Some seams and operations need to be done before others, and there is often a defined sequence that needs to be considered and worked through before sewing can begin.

9. Build. If individual panels or areas did not go as anticipated, they can be rebuilt – you might not need to finish the whole project first. And depending on the situation, you can learn more and push the project forward by learning from your mistakes. Few seams cannot be undone with a seam ripper (even if it is annoying and a step backward).

10. Use the result of all your hard work. First hand observation and testing is the best way to evaluate the overall effectiveness. Is it a good solution to the problem or goal? Evaluate the outcome – the good and bad; what went well, what was tough, what could go better next time – and improve on those aspects!

Document the final results and the process, for yourself and for others. Experiment, modify, and ultimately have fun! Sewing and the world of soft goods is a unique set of skills and knowledge, but the more you practice, the better and quicker projects will move along. Thanks for reading!

-Kirk Turner

Kirk Turner is an Industrial Designer, and has been bringing his brand of expertise to the Salient Team since 2015.

8 Reasons Getting Outside Makes You a More Creative Design Thinker

As a design and engineering consultancy, we feel living in Montana gives Salient a huge advantage in the realm of creativity and creative problem solving. It’s true that inspiration can be found just about anywhere – from backpacks dreamt up on mountain tops, to buildings modeled after crumpled up pieces of paper. However, we believe our energy and insight in the design world is fueled in part by gearing up, getting out, being immersed in and inspired by the details, forms, and colors of the wild, wide-open spaces that make this state so special. Not to mention the amount of hands-on testing and experimenting we get to do in this vast playground we call home!

In addition to funding personal projects with “Salient Initiatives” – which allow us to explore our curiosities in design – Salient offers many opportunities to employees that encourage us to get out and play in powder, take camping trips, and travel the world.

The following are just a few reasons we believe exploring and being active in the outdoors makes you a better design thinker:

Persistence: Try and fail, and try again

The tenant of Persistence is common in all outdoor recreations. As a first time ice climber, tackling the flows with Salient teammates this winter revealed muscles untrained, technique unrefined, and expectations that may not have matched reality. But failing fast, compelling forward, and trying until I physically couldn’t any longer are certainly traits I feel confident about bringing into my creative flow.

Noticing the Unnoticed: Taking time to slow down and zoom in (or out!)

Rock climbing is a big recreational activity for many at our office. As with many outdoor activities, while climbing you are 100 percent engaged, and focused on successfully sticking that next move – tackling one problem at a time. This focus, can bring a unique perspective, as you’re close enough to notice the things that remain unnoticed from a distance, like interestingly shaped pockets, colors, textures, and forms. Being on the rock promotes noticing these things in a different light than if one were to pass the whole rock face on a hike, or zip by on a bike – and can be truly eye-opening. Not only is this perspective inspiring as a designer, it also expands how I view these beautiful elements of nature. In good design, the simple, elegant, sometimes unnoticed details are the things that create a cohesive and complete product. If we can bring the practice of noticing the unnoticed into everyday life, it will surely bring a wealth of inspiration and perspective with it.

Simplify: Less is more

One of the first things we learn as designers is “less is more”! The “Simplify” concept translates seamlessly into lessons learned in the backcountry: bring less stuff. Not only will your outdoor experience be enhanced by forcing you to take in and use your surroundings, it will surely lighten up your pack, creating a more enjoyable hike to your destination. So, embrace the white space, use less text and fewer design elements for greater design-impact. A simpler, more focused, and intentional design often motivates better audience reaction.

Take Risks: Be daring!

Dare to think outside the box, and take the trail less traveled! The feeling while moving into the unknown isn’t always one that’s comfortable, there is often a sense unnerving shivers that flow throughout, and your mind almost always tries to talk you out of it. But taking conservative risks – in design as in adventure – will undoubtedly create a compelling experience that achieves the style-goal set and launches you into a feeling of pure bliss that leaves you wanting more. Rules and process are not absolute in design, but guidelines are there to get you started. Don’t be afraid to occasionally step off trail (when it’s smart), and take risks with your design, and creative thought process.

Propel your Practice: Human Powered

Most activities that are done here in the mountains are human powered. Whether skinning up a mountain to “earn your turns”, or placing cams to make your way up a gnarly crack on the side of a mountain to absorb the view from the top – you’re actively working for a result. The lesson of active work propelling my practice into success is one I find incredibly rewarding. Working hard, setting goals, and practicing your craft relentlessly will not only make you a stronger, faster designer, it will lead you to the level of refinement in your craft you strive for, and earn you the confidence to crush your goals in design, life, and adventuring.

Refresh: Make room in your mind from all of the confining details of everyday life

More room for creativity! Ever feel a little foggy after an average day plowing through your routine? The cure is raising that heartbeat, a bit of fresh air, or a sunset atop the highest point in town. I guarantee it. Gearing up, and getting outside makes you happier – It’s science! When you find yourself in a rut, to fuel your creative workflow sometimes all you need is a playful perspective. The fresh air and views create a great mindset for working through design problems. And when your mind is clear and refreshed, creativity has room to breathe, stretch, and settle into your next thoughtful design.

Turn Problems into Solutions: A positive and optimistic outlook is transformative

While venturing into unknown territory to in this case climb, surely has its benefits, it also means sometimes you get your vehicle stuck in the Kentucky backwoods and don’t have service to call for help… So rather than focusing on the problem at hand, and how unfortunate the situation happens to be. It’s helpful to get creative, stay positive, and makeshift a solution with the items you do have (sticks, debris, your own car mats) to get yourself out of there! The same is useful in design thinking, for example when designing furniture, sometimes toothpicks, popsicle sticks and tape can be your best friends to work through those tricky problems that arise as you try to move beyond the 2D form.

Biomimicry: Inspiration in Nature

“Biomimicry is an approach to innovation that seeks sustainable solutions to human challenges by emulating nature’s time-tested patterns and strategies. The goal is to create products, processes, and policies—new ways of living—that are well-adapted to life on earth over the long haul.” -the Biomimicry Institute

Nature often has solutions to problems present to humans that we have never even thought of, yet they have existed for years. A common approach to implementing these solutions into current products is to observe nature and its patterns, then sketch and develop based on the properties of these natural occurrences.

I know not everyone has national parks and mountain tops in their backyard, but just getting out to the park, the pond, the forest preserve, or your own back patio can make a big difference in your creative design thinking. So, now that you know how to channel these unique experiences into your creative process, I challenge you to find your adventure, get outside and expand your design thinking tool box!

Rebecca Allison is an Industrial Designer at Salient Technologies, Inc. She has a passion for the outdoors and soft goods design. In her spare time, Becca can be found adventuring in the mountains, or dreaming up footwear she’d like to make some day.

Innovation During a Pandemic

When the effects of COVID-19 began causing a shortage of personal protective equipment in America and Montana, Salient was quick to respond with design expertise. Salient designed an injection molded mask filter cartridge that is compatible with the standard 3M 6000 series masks to be mass produced in Montana. The team designed the mask in 3D CAD and then they 3D printed prototypes, which take about four hours each to 3D print. However, with injection molding, one filter cartridge can be produced in less than 60 seconds allowing for quick supply.

With a standard mask filter cartridge, it is difficult to sterilize the filter material inside. These cartridges must be thrown away. Salient designed a cartridge that easily opens by hand and snaps closed on all four sides. The N95-equivalent filter material can then be replaced or sterilized and reused. Salient’s previous experience designing many other various products allowed the Salient team to quickly respond and design a needed cartridge.

Salient is proud to collaborate with many other Montana entities in the effort to respond to COVID-19. As one of several companies that raised their hand to collaborate through the Montana Manufacturing Extension Center COVID-19 rapid response task force, Salient was appointed to oversee the design of the bayonet mount filter cartridges and compatible mask to ensure a quick and standardized response. Several injection molding shops around the state have expressed interest and are ready and willing to manufacture personal protective equipment for the state and beyond. Montana Tech is currently conducting testing on the Salient-designed filter cartridges to help validate the airflow as it moves through the certification process bringing it closer to full production.

Salient Product Design Mentorship

In partnership with HATCH, Salient is excited to announce we are now accepting applications for the 2015 Product Design Mentorship!

Launching in just a few short weeks, Salient will accept up to 6 candidates for our hands-on Mentorship. Good applicants are students who are (most likely) pursuing degrees in Mechanical Engineering, Industrial Design, Product Design or it’s equivalent – OR, those who have a marked interest in Product Design and the skills necessary to contribute to the program.

The Salient Mentorship is created in partnership with the HATCH 360 Mentorship that uses a bottom-up and peer to peer approach to build meaningful relationships, share knowledge and expertise, and challenge each other.

All students will be coached by Salient Technology owners – David Yakos and Stephen Sanford on Salient’s 3 Phase Design Process: 1) Concept Design, 2) Prototype Development, and 3) Design for Manufacturing, and invited to participate in all three ares on an actual project.

The Mentorship is not paid, nor is it for credit. The Application Deadline is Thursday, February 19th, and Classes will be held from 3 PM – 5 PM, Thursdays, March 5th, March 19th, April 2nd, and April 16th. Some work will be required outside of class time.

Email for more information and application forms.