Congratulations to the CA7CH Team and their amazing success! Just one week into their Kickstarter campaign, the CA7CH Lightbox project has more than doubled their $80,000 goal – and there are still over 20 days left to raise funds!

Lightbox is a tiny live-streaming, wearable camera maxing out at only 1.5 inches per side with a sleek aluminum body. This small, powerful waterproof camera connects with your Smartphone to make the experience of “catching” and sharing life’s moments easy, spontaneous and fun.

Here at Salient, we are delighted to have had a hand in the conceptual design and prototyping of the Lightbox camera housing and mounting system. Through industrial design, 3D modeling and many conversations with the CA7CH crew, we were able to fabricate prototypes and film-ready models to prep Lightbox for manufacturing and distribution.

Learn more about Lightbox and check out the CA7CH Kickstarter campaign by clicking on the image below. Good luck, CA7CH!

Visit our Website to see how we can help make your idea into the next success story!

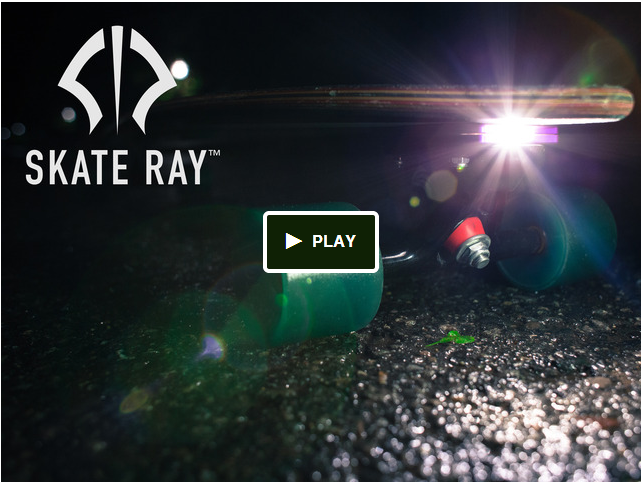

SkateRay Lights up the Night

“Salient helped me do what I could have never done alone: design a product that held true to my vision but could also be manufactured in quantity. Working with them is a perfect blend of professionalism and fun!”

~Martin Reaves, Skate Ray and Monolithic, LLC

Martin Reaves dreams of a better future. A future where skateboarders don’t have to be afraid of the dark. Enter the Skate Ray: a high power LED headlight for your board that lights up your path, illuminating obstacles so you can ride with the same confidence at night as you do during the day. Learn more about Skate Ray and check out the Kickstarter campaign by clicking on the image above.

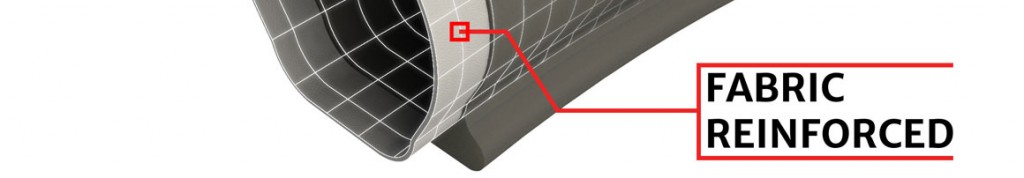

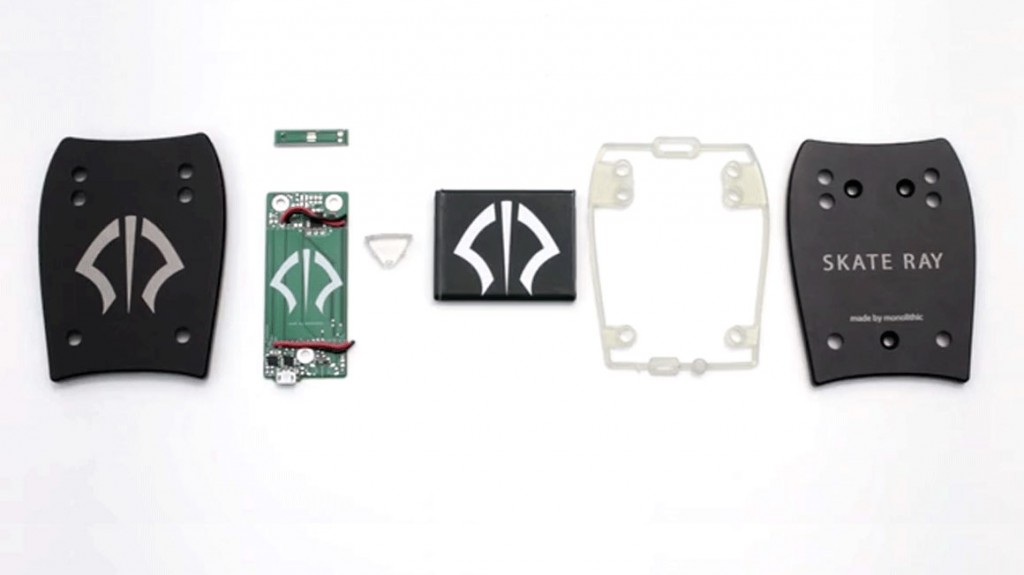

Designed to fit securely between your board and trucks, Skate Ray is built to take a beating and go anywhere your board goes. The slim profile light is housed in a sturdy aluminum casing with a custom gasket to keep out dirt and water. Indicator lights on the power button let you know when it’s time to hook up a mini-USB to the rechargeable lithium battery so you’re never left in the dark.

Hydaway Collapsible Bottle – Ingenious Hydration

“I couldn’t have built this product in the time-frame I did without the expertise of the Salient Team. They blend a great mix of engineered functionality and design aesthetic. I love that when we get to a problem we need to overcome it’s a group-think that benefits from many different perspectives. I’m very impressed with what they can accomplish – not only on my project but also the variety of others they’ve worked on…Especially considering how much time they spend in Nerf gun battles. :)”

– Niki Singlaub, Founder, Hydaway

The Hydaway Kickstarter campaign launched on August 10th and production is slated to begin this fall. Having already gained the attention of outdoor retailers like REI, Singlaub is confident the campaign will raise the funding needed to put the Hydaway into the hands of thirsty people.Click on the picture below to check out all the well thought out ideas and hard work behind Hydaway and quench your thirst for ingenuity!

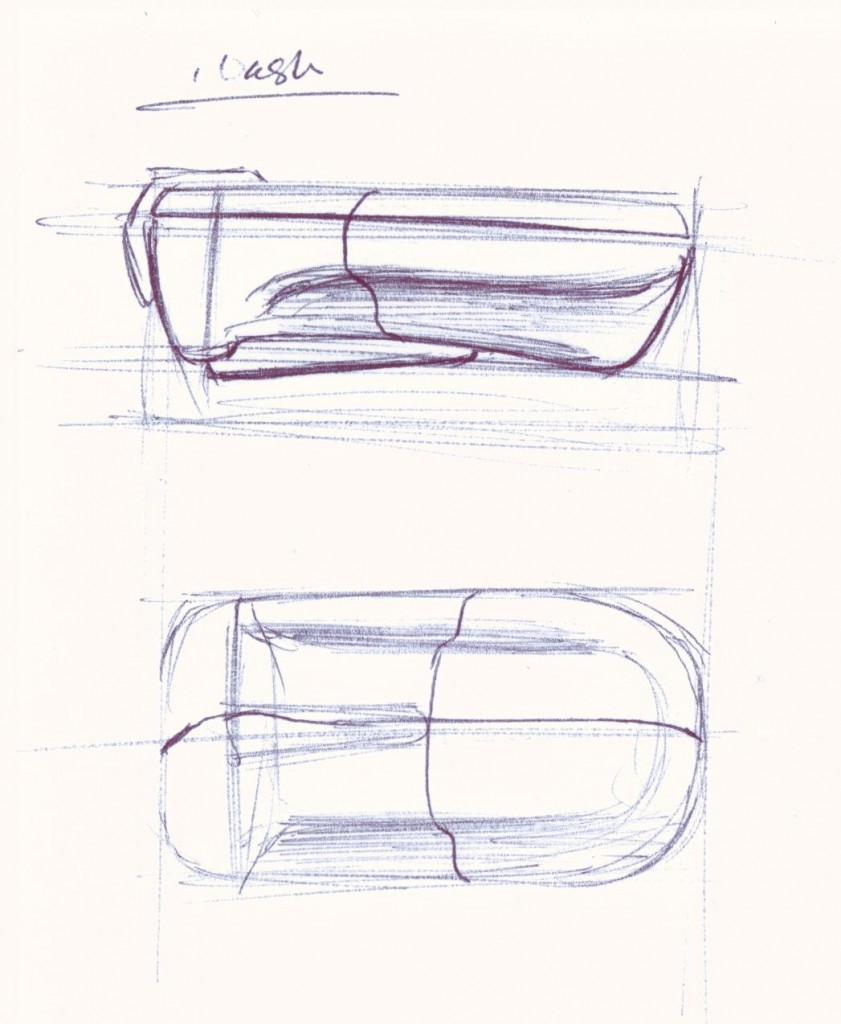

Conceptual Design: The Mechanical Development Process (in a Nutshell) Pt. 1

New products appear in company catalogs and on store shelves every season. We don’t often give thought to how they transformed from an individual idea to a tangible product. Remarkably, this mysterious process can be summed up in a few simple steps. Whether it is a new puzzle game or a complex valve for the space shuttle, there is a well-defined three-step route that nearly every product follows starting with a Conceptual Stage, followed by Prototype Stage, and finally the Production Stage. In this post, we’ll look at Step 1…

Conceptual Stage: Products start out as ideas which are often sparked by a challenge, competing product, gap in the market, inspiration from alternate industries, or the more unconventional “I woke up in the middle of the night with this great idea.” The first thing to do with this idea is write it down, move it from in-between your ears onto a piece of paper which, unlike humans, will never forget it. The conceptual stage has begun. Once on paper, an idea has hatched and can begin to grow. This is where brainstorming leads to the validation and the definition of the idea. Now’s a great time to be honest and ask some early questions: Does this already exist? Is there a market? Can it be made? What would it cost? What would I make it out of? Who would use it? What would it look like? Would people want it? And better yet, would they pay for it? Are there other ways of doing it? Should I protect it? Is it timely? Is it worth it?

The course of the product is often defined at this first and often least expensive stage. An industrial design sketch or conceptual CAD model at this stage may capture the look, materials and form which are carried all the way through prototype and production design. Many inventors only take an idea through the conceptual stage finishing with some quality sketches, renderings or perhaps an animation. At this point, the product concept is defined enough for market research, presenting to management, or attempting a licensing deal. However, in order to validate an idea or better sell the vision, one must often move into the Prototype Stage which we’ll explore in Part 2!

David Yakos is the VP, Director Creativity at Salient Technologies, Inc.

Prototype Design: The Mechanical Development Process (in a Nutshell), Part 2

In our last post, we explored Stage 1 of the Mechanical Development Process – the Conceptual Stage. In this post, we’ll explore Part 2 of 3, the Prototype Stage!

Prototype Stage: Once a plausible direction is determined by the conceptual stage, the prototype process can begin. The prototype stage is often repetitious as products evolve and develop. Prototypes are essential to validating a concept since they allow designers to test, feel, hold, use and experience the product in a way that a simple sketch or rendering cannot. It is wise to keep in mind the end goal of manufacturing when designing for a prototype to help narrow down materials and manufacturing processes. Often, prototypes are created as a “proof-of-concept” to validate form and functionality, and are also built as show-pieces to generate interest in a product. The prototype stage allows designers and inventors to catch flaws and visualize enhancements at a relatively early and inexpensive stage. Inventors stand a much better chance at generating interest in an idea if a concept is proven through the prototype stage rather than just a conceptual sketch.

The intricacy and cost of prototypes may vary greatly, but even an inexpensive prototype made from clay and cardboard can validate a concept. However, in order to validate a design a more sophisticated approach may be needed. More intricate prototypes can come from designs modeled in 3D CAD as a virtual prototype, then rapid prototyped (3D printed) and finished to represent a final product. Higher quality prototypes are essential for trade shows, marketing and confirmation of a concept prior to moving into the production stage. Taking a solid idea this far is a strong position for the independent inventor looking to license the product. Prior to production, companies will often make changes to a design, so unless the inventor is the one manufacturing and distributing the product, it makes sense to hold off on investing beyond the prototype stage.

Check out the final part of this series, the Production Stage!

David Yakos is the VP, Director Creativity at Salient Technologies, Inc.

Production Design: The Mechanical Development Process (in a Nutshell), Part 3

Last time, we took a look at Stage 2 of the Mechanical Development Process – the Prototyping Stage. We’ve also explored Stage 1 – the Conceptual Stage in a previous post. Here, we’ll be delving into the third and final part of the Mechanical Development Process – the Production Stage!

Production Stage: The final stage of mechanical development is the Production Stage where, once a concept has been validated through market research and prototype testing, the final design changes take place. Production design is often finalized by the product company, manufacturing facility or by a third party consulting firm. Sometimes this calls for a final “production-ready” prototype as many companies and manufactures find prototypes of this nature necessary for to validating the design prior to investing in expensive tooling and inventory. Final tweaks occur at this stage to ensure manufacturability and to reflect cost considerations. This final design, excluding versions 2.0, 3.0 etc, include manufacturing methods, 2D engineering drawings, 3D CAD files, materials selections and fully defines all components.

Most successful products follow this three stage process. A bit of variation exists as some simple projects seem to fly through straight to the store shelf while others require a bit of iteration and testing. However, they all typically touch on Concept, Prototype and Production, in that order. It’s important to keep the entire process in mind while developing. For example, ask at the early stage, “Can this be made?”; and when it is ready for tooling ask, “Is this the product we intended from the beginning?” While being cognizant of the whole path, one does not want to skip ahead or miss necessary steps. Since each stage requires greater investment than the previous one, it behooves inventors and companies to move in the proper order of development so they don’t spend unnecessarily. Following these stages also helps define how far along a project really is and better determines the current value of an idea. The closer an idea is to becoming a product, the more it is worth!

David Yakos is the VP, Director of Creativity at Salient Technologies, Inc.

The Importance of an Animation – Using 3D CAD to Tell Stories

If a picture is worth a thousands words, then at 30 frames per second, a video is worth its weight in gold…

In the product design world, a high value is placed on sharing ideas, which springboard to greater things. Animations are helpful for both proof of concept prior to an idea being fully fleshed out and for products that are ready to manufacture. Today, videos play a pivotal role in getting a product seen by the right person or group, and often lead to purchase or licensing agreements. With social media playing such a large role in our society, creating a video that highlights the key features of your design and why it stands apart from others can be a key player in getting a product to market.

Take Kickstarter for example. Each crowd-funding campaign is required to have a video to share the story behind the idea of what’s being pitched and all the elements that make this particular product worth monetary backing. Frequently, these products are still in a prototype phase, so the value of an animation is immeasurable in being able to paint a picture of something that could potentially exist, but needs funding to actually reach the manufacturing stage.

Earlier this year, Seal Master Corporation approached Salient Technologies, Inc. for help showcasing a product. Using 3D CAD and video editing software, the STI Team was able to provide Seal Master with a technical animation showcasing their inflatable seals and the components that set it apart from the competition. Salient delivered the video they envisioned to communicate product features to potential client and grow their business.

Check out the video animation below:

After working with STI, Dan Jackson, IT Manager for Seal Master Corporation had only good things to say:

“Salient Technologies has been wonderful to work with. From initial draft to final revision, our animation has been created exactly how we envisioned. When many other design firms fell short with our concept, Salient had the knowledge and vision to deliver. They provide quality work for a fair price. Looking forward to working with them in the future for all of our technical animation needs.”

Let Salient Technologies, Inc. help share your idea and vision through the power of animation!

Thinking of You… Designing for the End User

Standing in the greeting card section of my local box store, I noticed a lot of “Thinking of You” cards. Tasked with finding an appropriate birthday card, I thought, “you really have to be an intentional and thoughtful person to get a ‘just-because’, Thinking of You card for someone.” You know the cards… they’re sappy, like, “The other day I was smiling for no reason, but then I realized I was thinking of you”; or snappy, like, “Just thinking of you… which reminds me… you owe me twenty bucks.” As product designers, we have to take this intentional and thoughtful approach in crafting our ideas if we really want to connect with the End User. Buying a card, we know the recipient needs to be cheered up because they had a bad week, or loved on because they are excessively sentimental and feed off the sap. The intent of focusing on the reader’s or users’ needs can be called “user-centered design”.

like, “The other day I was smiling for no reason, but then I realized I was thinking of you”; or snappy, like, “Just thinking of you… which reminds me… you owe me twenty bucks.” As product designers, we have to take this intentional and thoughtful approach in crafting our ideas if we really want to connect with the End User. Buying a card, we know the recipient needs to be cheered up because they had a bad week, or loved on because they are excessively sentimental and feed off the sap. The intent of focusing on the reader’s or users’ needs can be called “user-centered design”.

In User-Centered Design, we need to look at who this End User is from the very early stage of designing a product. We try to foresee the little girl, old man or even the puppy who will be using the product. Doing this requires diving into imagination, dreaming up personas and asking questions of them: Will they intuitively know how to use the product without reading the instructions? Will they use it in extreme environments? How will they hold it? Where will they store it? With what will they clean it? Will they try to eat it? In product design, we’re sometimes guilty of jumping right into feature-based design with ideas biased by personal experience and desire… “I want it to look like an iPhone. I want it water-proof and it should be yellowish-orange because I think Apple is the greatest, I’m a swimmer and I really love yellowish-orange…” What happened to the thoughtful and intentional designer; the kind that buys thinking of you cards? Ask questions!

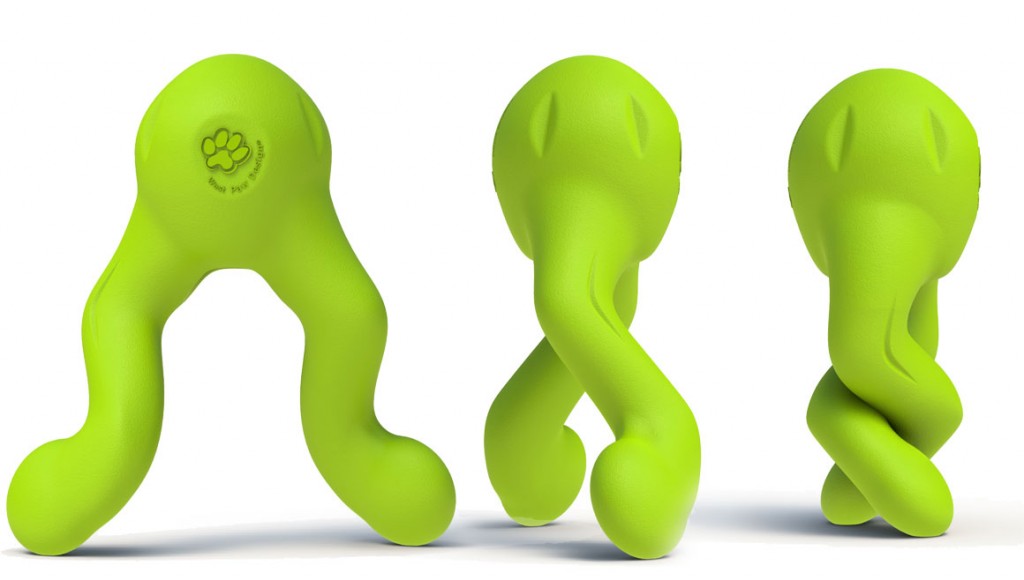

One fun example of asking questions for thoughtful End User design occurs when creating a new dog toy. When developing dog toys we have to ask, “Who is the End User and what will they do with it?” Obvious, right?… it’s the dog. But, when you think about it further… the End User of a dog toy is two-fold: a partnership between the pup and its owner. Both the dog and his master want endless play out of the toy.  The form has to be such that the teeth of the k9 can grab but cannot easily catch and cut into the toy, encouraging a long-lasting chew. At the same time, it has to fit the hands of the owner who has to pick it up and throw it. Will it be covered in slobber when it’s grabbed? Is there a place that would be easier to hold on? Will it hold a treat and if so, how hard will it be for the dog to get it out? Will we discourage the dog or keep him entertained? How will it fly if thrown? Is the dog owner environmentally conscious and would they prefer an eco-friendly material? Does it matter to the owner where the product was made? Would they clean it if it was an easy process? Will this product ever end up in a pond and if so, should it float? How will this product make them feel? Yep, we have to talk about feelings.

The form has to be such that the teeth of the k9 can grab but cannot easily catch and cut into the toy, encouraging a long-lasting chew. At the same time, it has to fit the hands of the owner who has to pick it up and throw it. Will it be covered in slobber when it’s grabbed? Is there a place that would be easier to hold on? Will it hold a treat and if so, how hard will it be for the dog to get it out? Will we discourage the dog or keep him entertained? How will it fly if thrown? Is the dog owner environmentally conscious and would they prefer an eco-friendly material? Does it matter to the owner where the product was made? Would they clean it if it was an easy process? Will this product ever end up in a pond and if so, should it float? How will this product make them feel? Yep, we have to talk about feelings.

In developing West Paw Design’s Tizzi, we envisioned a dog toy that could offer virtually endless play. We accomplished this by focusing on interactions between the users and toy while playing at the park or at home – not on the toy itself. Through our questions it was revealed that the form could not have sharp edges that would tear if a tooth got caught. In a game of tug-of-war there had to be room for teeth and fingers. If part of the toy became covered in slobber there had to be other grabbing options, or at least a texture to help mitigate the mess. A treat could be hidden in a chamber and the handles twisted and locked to allow for indoor play – possibly on the kitchen floor. The treat chamber would encourage prolonged play for the dogs with obsessive personalities…but what about a high energy dog at the park? On the Tizzi, when the handles are twisted and locked the age-old game of fetch is enhanced by a toy that flies like a spiral thrown football resulting in even more fun for both End Users.

With more questions answered, we select an appropriate material. The award-winning ZogoFlex material offers indestructibility, is recyclable, non-toxic, dishwasher safe, can be made in the USA and it is less dense than water allowing it to float if thrown into a pond or lake. Material selection alone allowed us to hit some major design criteria which were defined by focusing on the End User’s experience. Ultimately, we were successful in creating a product that makes the dog and owner feel good – good about getting exercise, good about environmentally conscious purchases and good about the enhanced relationship after solid playtime.

By asking and answering questions like these, we narrow down the intent of the product which governs the form and final function – not the other way around. We become intentional designers by just Thinking of You…

David Yakos is VP and Director of Creativity at Salient Technologies, Inc.

“In The Making” – An Inside Look at the Design Process

Sharing an inside look at our design process and the journey of one of our current projects is pretty exciting – especially when it’s with Doc Mike North, host of In the Making.

In the Making takes viewers behind the scenes of spectacular projects, people and ideas while they are being created. Doc North travels the world to give viewers an inspirational look into what it takes to make scientific breakthroughs, create companies and invent the future. Follow North to catch the next big thing while it’s still IN THE MAKING.

In this episode of In the Making, we’re exploring a new, non-lethal weapon alternative and sharing a bit of the developmental process by showcasing concept design, prototyping and production design. The non-lethal pepper spray attachment mounts to any standard picatinny rail and has a range of approximately 30 feet to assist in defusing hostile situations.

Developing a product that’s used in the field means several prototypes versions are necessary to test the feel and function of the device. It’s important that a product feels right when in hand, which isn’t something that can be determined from a digital CAD file. The product has to feel robust, secure, made for the hand, and easy to operate. In testing this product, we found physical testing helpful in figuring out nozzle size and ensuring the pepper spray reached the correct distance. We also tested and perfected one hand operation including firing, loading and reloading.

The aim in designing this product is to save the lives of people who are unnecessarily shot due to chaotic series’ of events ending in lethal force. Officers are often called to enter situations without knowing the true nature of the environment and whether they will need to be armed with lethal or non-lethal force. This product gives law enforcement an option other than lethal force without endangering themselves or civilians by needing to lowering their firearm to switch tools in the midst of conflict. Now, hostile environments that are escalating to a high-risk situation can be quickly defused before they end in a fatal shooting. Our goal is providing an alternative to lethal force by making a product that matters.

Thank you, Doc North, for your time and energy!

David Yakos is VP and Director of Creativity at Salient Technologies, Inc.

Taking Ideas from Good to Great

“Salient has been a vital part of The Ripple product development process, not only from an engineering perspective, but also in terms of design conception and education. Developing an innovative and functional product is not a black and white process and what separates Salient from the competition is their willingness to dive in and explore all the possible ways your product can look and function. I would definitely recommend Salient to anyone who is ready to turn their idea into a reality.” – Kevin Scharfe, Founder, Warum Studios, LLC

Here at Salient, we get to work with lots of people who have really good ideas, and we love nothing more than helping our clients develop their good ideas into great ideas. So when Warum Studios, LLC approached us with The Ripple, we knew it could be a great product, and the collaboration began.

With some “expert tweaking” – including improving on the bayonet design, size and depth of the bowl, and the ergonomic handle design – Salient kicked out manufacturing files, and The Ripple began a Kickstarter campaign to fund the next phase in production. In a little over a month, Warum Studios was able to raise almost $30,000 in Kickstarter backing, collect market research and narrow down their target market to people in their 20’s who live in dorms or small apartments; young families and the disabled.

Now, 10 months after producing their first run, founder Kevin Scharf is proud to say they’ve sold almost 4,000 Ripples to customers all over the world! “What makes The Ripple truly special”, says Scharf, “is not that it’s a detachable bowl and plate, but the possibilities for different dishes and devices that can connect quickly and securely with our bayonet mount. We are now in the market research phase of adding a smaller bowl to the lineup for kids and possibly a dipping cup/drink holder!”

The Ripple is currently available in retail stores across Montana and was recently published in Japan’s version of the Wall street Journal. Friday, November 14th, you can tune into the DIY Network hit show, “I Want That”, at 9 PM Mountain Time, to see The Ripple featured as one of the shows coveted items. The Ripple has also been accepted into the “Discover Design” section of the juried Chicago-based International Housewares Show in February 2015. But, if you can’t make it to Chicago, you can purchase your very own Ripple HERE.