As a design and engineering consultancy, we feel living in Montana gives Salient a huge advantage in the realm of creativity and creative problem solving. It’s true that inspiration can be found just about anywhere – from backpacks dreamt up on mountain tops, to buildings modeled after crumpled up pieces of paper. However, we believe our energy and insight in the design world is fueled in part by gearing up, getting out, being immersed in and inspired by the details, forms, and colors of the wild, wide-open spaces that make this state so special. Not to mention the amount of hands-on testing and experimenting we get to do in this vast playground we call home!

In addition to funding personal projects with “Salient Initiatives” – which allow us to explore our curiosities in design – Salient offers many opportunities to employees that encourage us to get out and play in powder, take camping trips, and travel the world.

The following are just a few reasons we believe exploring and being active in the outdoors makes you a better design thinker:

Persistence: Try and fail, and try again

The tenant of Persistence is common in all outdoor recreations. As a first time ice climber, tackling the flows with Salient teammates this winter revealed muscles untrained, technique unrefined, and expectations that may not have matched reality. But failing fast, compelling forward, and trying until I physically couldn’t any longer are certainly traits I feel confident about bringing into my creative flow.

Noticing the Unnoticed: Taking time to slow down and zoom in (or out!)

Rock climbing is a big recreational activity for many at our office. As with many outdoor activities, while climbing you are 100 percent engaged, and focused on successfully sticking that next move – tackling one problem at a time. This focus, can bring a unique perspective, as you’re close enough to notice the things that remain unnoticed from a distance, like interestingly shaped pockets, colors, textures, and forms. Being on the rock promotes noticing these things in a different light than if one were to pass the whole rock face on a hike, or zip by on a bike – and can be truly eye-opening. Not only is this perspective inspiring as a designer, it also expands how I view these beautiful elements of nature. In good design, the simple, elegant, sometimes unnoticed details are the things that create a cohesive and complete product. If we can bring the practice of noticing the unnoticed into everyday life, it will surely bring a wealth of inspiration and perspective with it.

Simplify: Less is more

One of the first things we learn as designers is “less is more”! The “Simplify” concept translates seamlessly into lessons learned in the backcountry: bring less stuff. Not only will your outdoor experience be enhanced by forcing you to take in and use your surroundings, it will surely lighten up your pack, creating a more enjoyable hike to your destination. So, embrace the white space, use less text and fewer design elements for greater design-impact. A simpler, more focused, and intentional design often motivates better audience reaction.

Take Risks: Be daring!

Dare to think outside the box, and take the trail less traveled! The feeling while moving into the unknown isn’t always one that’s comfortable, there is often a sense unnerving shivers that flow throughout, and your mind almost always tries to talk you out of it. But taking conservative risks – in design as in adventure – will undoubtedly create a compelling experience that achieves the style-goal set and launches you into a feeling of pure bliss that leaves you wanting more. Rules and process are not absolute in design, but guidelines are there to get you started. Don’t be afraid to occasionally step off trail (when it’s smart), and take risks with your design, and creative thought process.

Propel your Practice: Human Powered

Most activities that are done here in the mountains are human powered. Whether skinning up a mountain to “earn your turns”, or placing cams to make your way up a gnarly crack on the side of a mountain to absorb the view from the top – you’re actively working for a result. The lesson of active work propelling my practice into success is one I find incredibly rewarding. Working hard, setting goals, and practicing your craft relentlessly will not only make you a stronger, faster designer, it will lead you to the level of refinement in your craft you strive for, and earn you the confidence to crush your goals in design, life, and adventuring.

Refresh: Make room in your mind from all of the confining details of everyday life

More room for creativity! Ever feel a little foggy after an average day plowing through your routine? The cure is raising that heartbeat, a bit of fresh air, or a sunset atop the highest point in town. I guarantee it. Gearing up, and getting outside makes you happier – It’s science! When you find yourself in a rut, to fuel your creative workflow sometimes all you need is a playful perspective. The fresh air and views create a great mindset for working through design problems. And when your mind is clear and refreshed, creativity has room to breathe, stretch, and settle into your next thoughtful design.

Turn Problems into Solutions: A positive and optimistic outlook is transformative

While venturing into unknown territory to in this case climb, surely has its benefits, it also means sometimes you get your vehicle stuck in the Kentucky backwoods and don’t have service to call for help… So rather than focusing on the problem at hand, and how unfortunate the situation happens to be. It’s helpful to get creative, stay positive, and makeshift a solution with the items you do have (sticks, debris, your own car mats) to get yourself out of there! The same is useful in design thinking, for example when designing furniture, sometimes toothpicks, popsicle sticks and tape can be your best friends to work through those tricky problems that arise as you try to move beyond the 2D form.

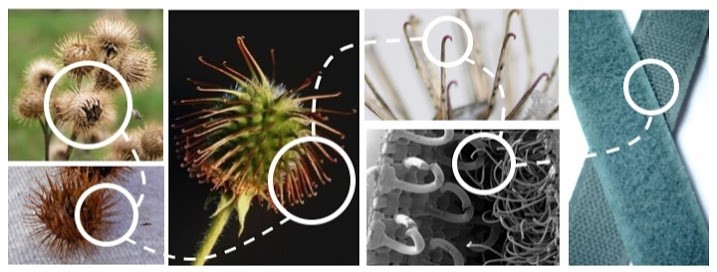

Image via: https://www.wildability.com/biomimicry/

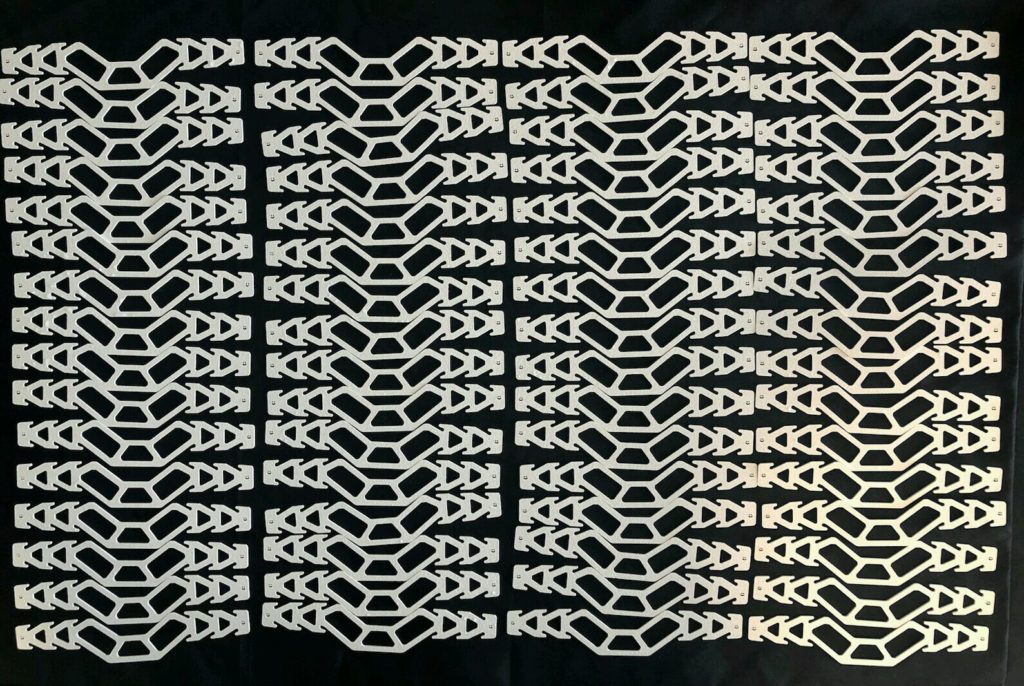

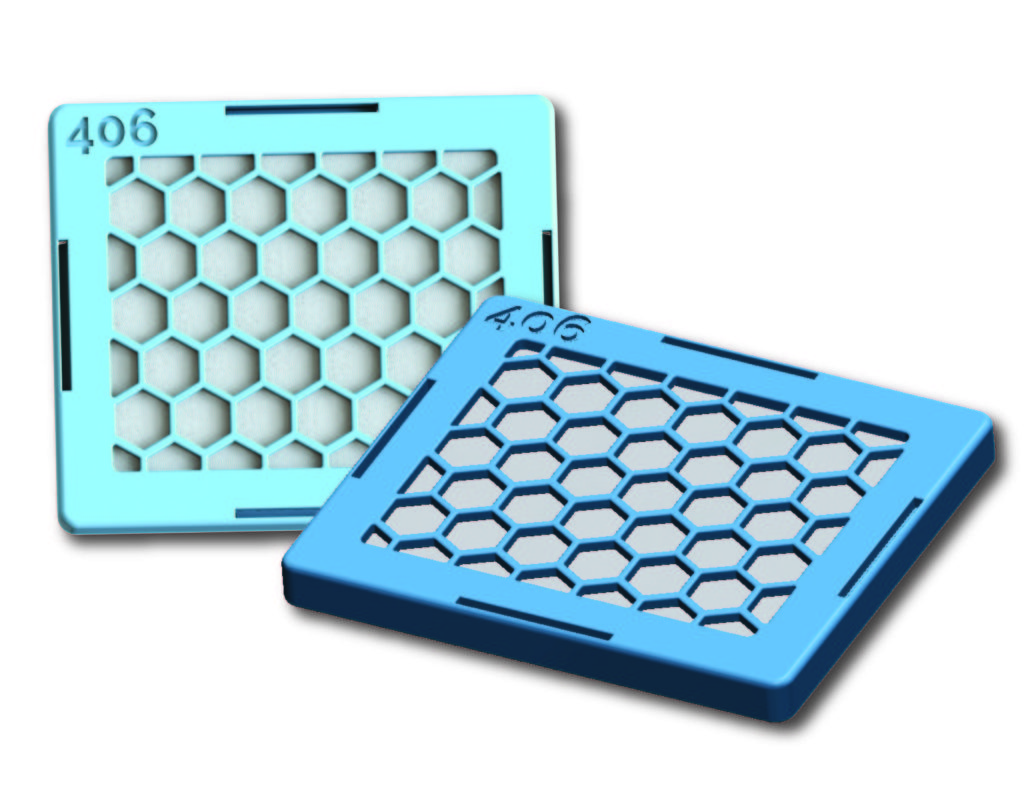

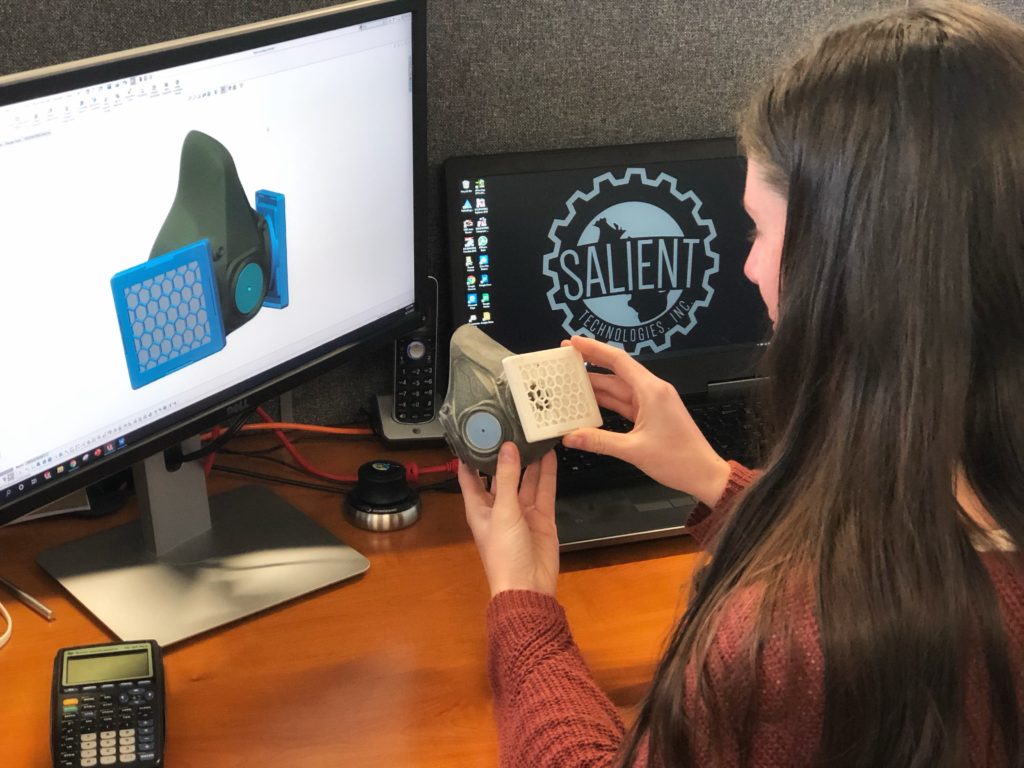

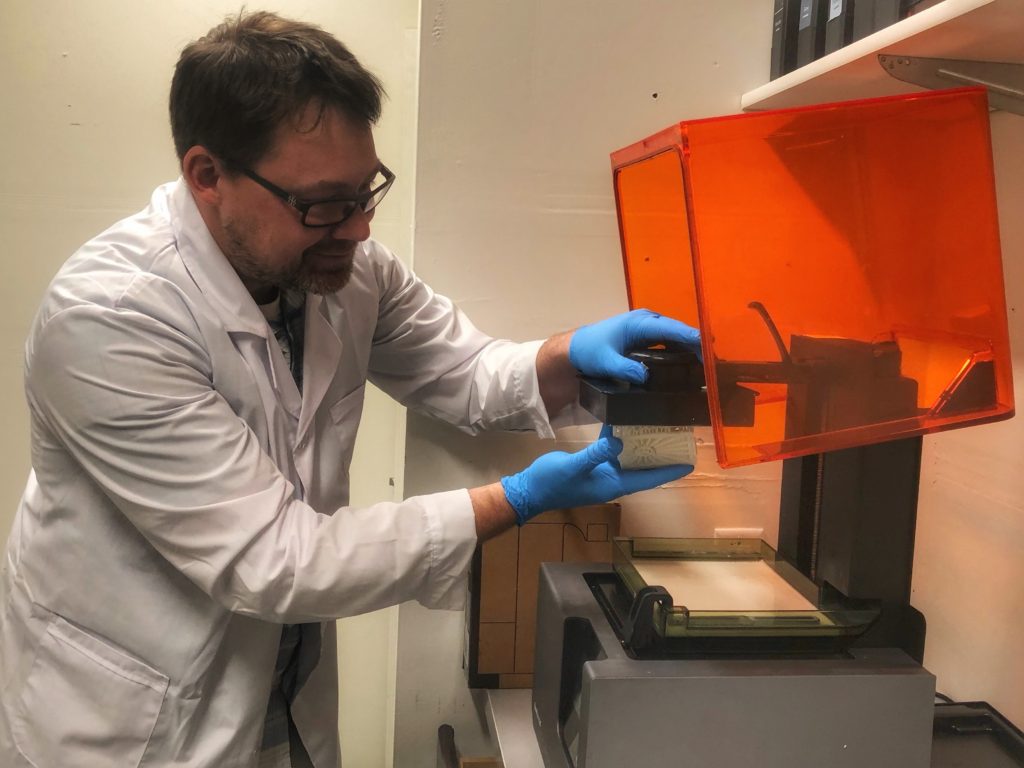

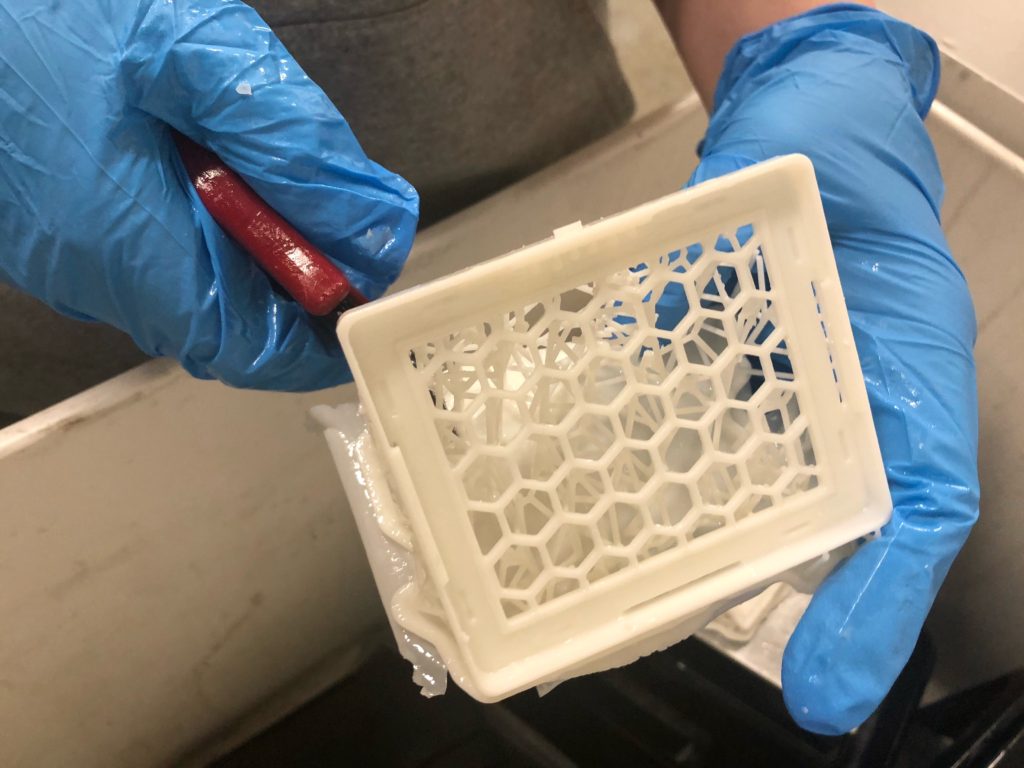

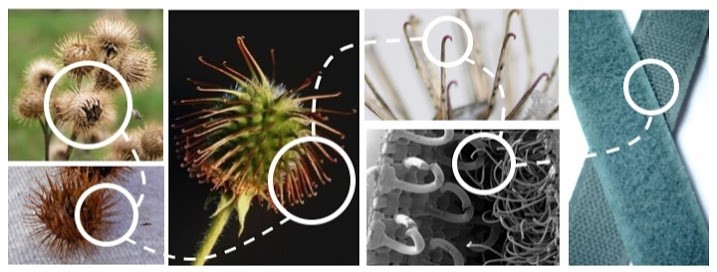

Biomimicry: Inspiration in Nature

“Biomimicry is an approach to innovation that seeks sustainable solutions to human challenges by emulating nature’s time-tested patterns and strategies. The goal is to create products, processes, and policies—new ways of living—that are well-adapted to life on earth over the long haul.” -the Biomimicry Institute

Nature often has solutions to problems present to humans that we have never even thought of, yet they have existed for years. A common approach to implementing these solutions into current products is to observe nature and its patterns, then sketch and develop based on the properties of these natural occurrences.

I know not everyone has national parks and mountain tops in their backyard, but just getting out to the park, the pond, the forest preserve, or your own back patio can make a big difference in your creative design thinking. So, now that you know how to channel these unique experiences into your creative process, I challenge you to find your adventure, get outside and expand your design thinking tool box!

Rebecca Allison is an Industrial Designer at Salient Technologies, Inc. She has a passion for the outdoors and soft goods design. In her spare time, Becca can be found adventuring in the mountains, or dreaming up footwear she’d like to make some day.